Reedbut Group has taken a bold step toward sustainability at its new Milton Keynes facility by partnering with Treco Ltd, one of the UK’s leading biomass heating specialists, to install a renewable biomass boiler as part of a wider, energy-efficient factory heating system.

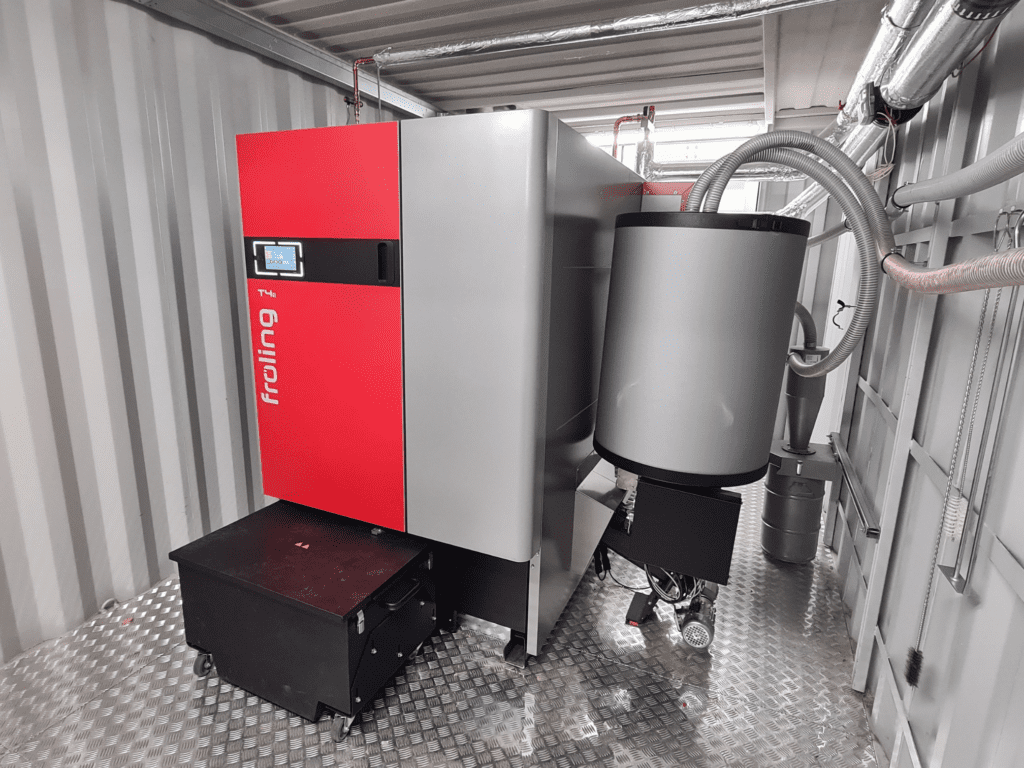

The fully automated, high-efficiency Froling 300kW wood pellet boiler, complete with a 12-ton fuel silo and temperature-maintained thermal store, now provides the site with a stable supply of renewable heat. Maintaining the heat store at a constant temperature increases system efficiency, allowing hot water to flow through to a heat-exchange system, where large fans convert this energy into warm air distributed throughout the factory and warehouse.

“Sustainability sits at the heart of everything we do—not just in our products, but in how we power our business,” said Stuart Deaton, Group Customer Experience Director. “Switching to biomass and integrating it with smart recirculation systems dramatically cuts our carbon footprint and futureproofs our operations for decades to come.”

Treco, with more than 700 biomass systems installed nationwide, delivered Reedbut a complete solution from design and offsite construction to installation, commissioning, and staff training. The system features advanced technology from Froling GmbH, whose award-winning biomass engineering recently earned the 2025 Plus X Award for Best Brand of the Year.

“Getting the warehouse up and running in just a few months took a lot of coordination, and I’m proud to say Treco played a key role in making it happen,” said Keith Hadley, Project Manager at Treco. “The biomass boiler and VTS heater system are now helping Reedbut Group operate efficiently and sustainably.”

Beyond renewable heat, Reedbut’s factory site incorporates an interconnected system that significantly increases energy efficiency. Warm air generated by production machinery is vacuumed off and cleaned through specialist air-filter towers, working alongside a trim extraction setup supplied by Impact Air Systems. Once filtered, this clean, warm air is recirculated back into the building, helping maintain both temperature and positive air pressure, reduce heat loss, and ensure a cleaner working environment.

Waste material is baled with a semi-automatic baler from Capital Compactors for easy handling. These half-tonne bales, collected and processed by FuturFirst, streamline the recycling process and support Reedbut’s commitment to a circular, low-waste manufacturing approach.

Thanks to this fully integrated system—biomass heating, intelligent air recirculation, and efficient waste handling—Reedbut’s new site uses less than 10% of the energy typically required for a factory of its size. This saves around 150,000kWh of energy annually and offsets the CO₂ emissions of up to seven cars every year.

With this investment, Reedbut Group continues to lead the way in greener manufacturing, demonstrating how to protect the environment and support the UK’s Net Zero ambitions in alignment with business goals.

For more information, visit our website here.