As an apprentice straight out of school, Mark Goodman learnt the skills needed to succeed in the competitive world of precision engineering – something that stood him in good stead for a future among some of the biggest driving forces in manufacturing excellence.

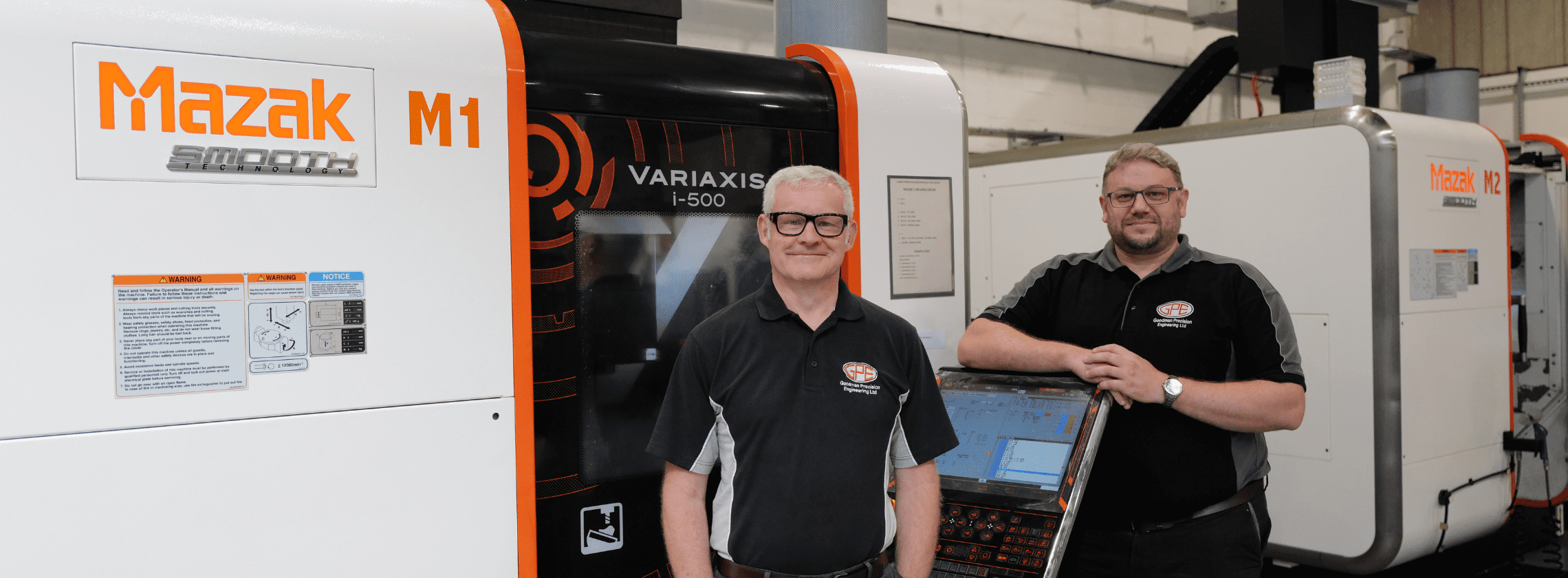

After honing his skills with the likes of Ilmor, Red Bull and Cosworth, Mark founded his own company, Goodman Precision Engineering in Milton Keynes 15 years ago and today the firm stands as a testament to what can happen when innovation and precision are closely aligned.

The company has carved a niche in the competitive world of high-quality, precision components manufacturing, playing a significant part in technology that has been transformational in Formula 1 and is still feeding into improvements to vehicles in day-to-day life.

Goodman Precision Engineering’s state-of-the-art facility in Stacey Bushes operates around the clock. Equipped with cutting-edge CNC milling and turning capabilities, as well as comprehensive inspection services, the manufacturing operation ensures every component it produces meets the exacting standards of a diverse client base, ranging from leading motorsport and automotive clients to defence, rail, energy production and beyond.

In establishing his own company, Mark and his team bring their skills to partnerships with clients across the region, providing manufacturing solutions to facilitate the development, improvement and production of specialist components that play a small but incredibly important part in so many products.

The team’s involvement in pioneering projects, such as the development of KERS (Kinetic Energy Recovery System) with key clients in Milton Keynes, underscores its ability to push the boundaries of what is possible.

Mark said:

“Electrification and hybrid technology has transformed motor sport. F1 leads the way in terms of the research and development and what they are trying to achieve. The aim is to get these motors as small and compact as possible, high power density is what everyone is looking for, chasing new methods and materials that can make a difference to efficiency and performance.

“What is fantastic is how the development has fed down into hypercars and supercars, and now into your standard commuter EV. We are also seeing similar developments in other sectors, such as marine or defence.”

Goodman Precision Engineering works with a wide array of materials, including aluminium, steel, stainless steel, titanium, AMC (aluminium metal composite) and plastics to name but a few. This versatility means it caters to the unique needs of each customer, providing tailored solutions.

The foundation of its success lies in the combined expertise of a management team that collectively boasts over 50 years of experience in the Formula 1 and motorsport industry. That well of knowledge and enthusiasm for technological advancement fuels a commitment to continuous improvement.

Until the budget cap was introduced, Formula 1 constituted 60% of Gooodman Precision Engineering’s business. It’s still significant, at around 30%, but the rule change vindicated the firm’s strategic commitment to diversification. The transition has been seamless, thanks to the reputation for excellence and the trust the firm has built with its customers.

Goodman Precision Engineering understands that continuous investment in the future is key to maintaining a competitive advantage, whether that’s in harnessing the latest equipment or enhancing the skills of the workforce.

Find out more about Goodman Precision Engineering on 01908 470880, email sales@goodmanpe.co.uk or visit www.goodmanpe.co.uk